What is perforated aluminum plate

Perforated aluminum plate refers to a rectangular material with a rectangular cross section and uniform thickness obtained by pressure processing (shearing or sawing) of pure aluminum or aluminum alloy materials.In fact, it is a metal aluminum plate with holes, also known as punched aluminum plate, perforated metal plate, and perforated screen.

Perforated aluminum plate is a new material that reduces noise and has decorative effects.

Material performance and characteristics

Time-honored, high temperature resistance, corrosion resistance, fire resistance, moisture resistance, shock resistance, and good chemical stability. Even if it is exposed to the sun and rain, the perforated aluminum plate remains consistent, and its practicality is not inferior to marble tiles;Compared with other metal materials, the surface is very smooth, without burrs or other defects;

The structure is light and stable. The application of lightweight aluminum plate combined with perforation reduces the weight of the material, which is very beneficial to the load-bearing structure and the lightness of the rod design. The process is simple and easy to install and maintain.

Sustainability, some perforated aluminum plates are 100% recyclable. The sheet is eco-friendly and can contribute to LEED certification. The perforated sheet with PVDF coating has strong resistance to oxidation and harsh external conditions;

The physical environment of the building is good, and the perforated aluminum sheet greatly reduces the shading coefficient of the glass, filters the dazzling daylight into diffuse light, thereby reducing the impact of solar radiation on the interior, which can help create a more favorable working environment and stable indoor temperature. The ventilation and light transmittance are very good. Even if the smallest aperture is only 0.5mm, it can meet the indoor needs, and the most important thing is that it can play an anti-theft effect;

The sight is wide. When you want to look into the distance, you can move left and right, up and down to open it, which will not hinder your sight at all, and it also plays the role of a guardrail;

The shape is beautiful, the design is simple and vivid, and it can be perforated in different ways. Through regular perforations, patterns are formed to achieve diversified shapes. Strong three-dimensional sense and good decorative effect.

The appearance is more impactful. Perforated aluminum sheets can be used to cover parking lots, cover air devices, duct systems and pipes, and create signs. This helps to improve the visual appeal of different spaces while providing functional advantages such as weather protection and temperature control;

Types of perforated aluminum plates

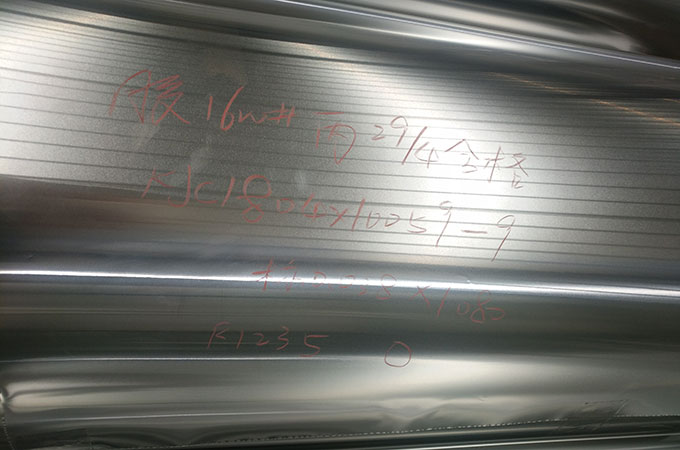

According to alloy composition, they are divided into: high-purity aluminum plates, pure aluminum plates, alloy aluminum plates, composite aluminum plates or brazed plates and aluminum-clad aluminum plates, etc.According to thickness, they are divided into: thin plates (0.15mm-2.0mm), conventional plates (2.0mm-6.0mm), medium plates (6.0mm-25.0mm), thick plates (25mm-200mm), five-rib pattern aluminum plates and ultra-thick plates (>200mm), etc.

According to the type of punching technology, they can be divided into: pattern punching mesh, formed punching mesh, heavy punching mesh, ultra-thin punching mesh, micro-hole punching mesh, wire-cut punching mesh, laser punching mesh, etc.

Affected by factors such as processing cost, unit weight, unit flatness, etc., the thickness of perforated aluminum plates is often selected from 1.0mm to 6.0mm.

Internationally, it is customary to divide it into the following three categories:

1. Aluminum plate (aluminum sheet): aluminum material with thickness>0.2mm, 200mm<width≤500mm, and length≤16m;

2. Aluminum bar (aluminum strip): aluminum material with thickness>0.2mm and width≤200mm; (With the advancement of large equipment, there are more bars with a maximum width of 600mm);

3. Aluminum foil: aluminum material with a thickness≤0.2mm.

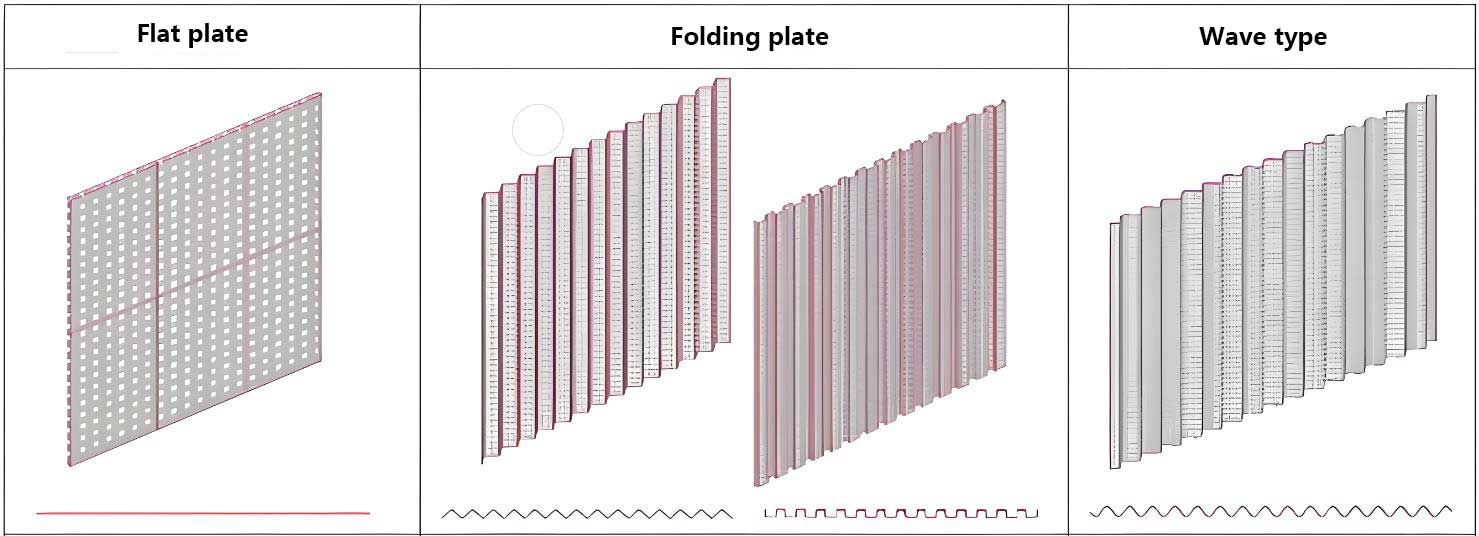

Plate type classification

The plate type can be divided into flat plate, folded plate, wavy, serrated and short-side folded plate. With the increase of perforation rate, the strength of perforated aluminum plate tends to weaken. The choice of plate type affects the strength of perforated aluminum plate, and then affects the size of perforated aluminum plate module, the number of keels that play a connecting role, and the overall effect expression.

Flat plate

The perforated aluminum plate first appeared in the form of a flat plate, because the processing technology of the flat plate is relatively simple and it is the most widely used.Advantages: The interface of the board is very flat, the arrangement of holes is more free, which is suitable for patterned hole arrangement design, the line of sight is more transparent, and it is conducive to the overall expression of the building.

Folding plate type

It is formed by folding on the basis of the folding plate type. Folding is actually equivalent to greatly increasing its own structural thickness, so the strength is greatly improved, which can reduce the vertical division and seam connection of the board, greatly reduce the number of vertical keels, and save the cost of structural components.

Wave type

It is made by bending the plate through an arc. Its characteristics are similar to those of the folding plate type, but the wave-shaped perforated aluminum plate can form a more hazy and ambiguous translucent atmosphere, and its softened interface contour is easier to integrate into the environment.

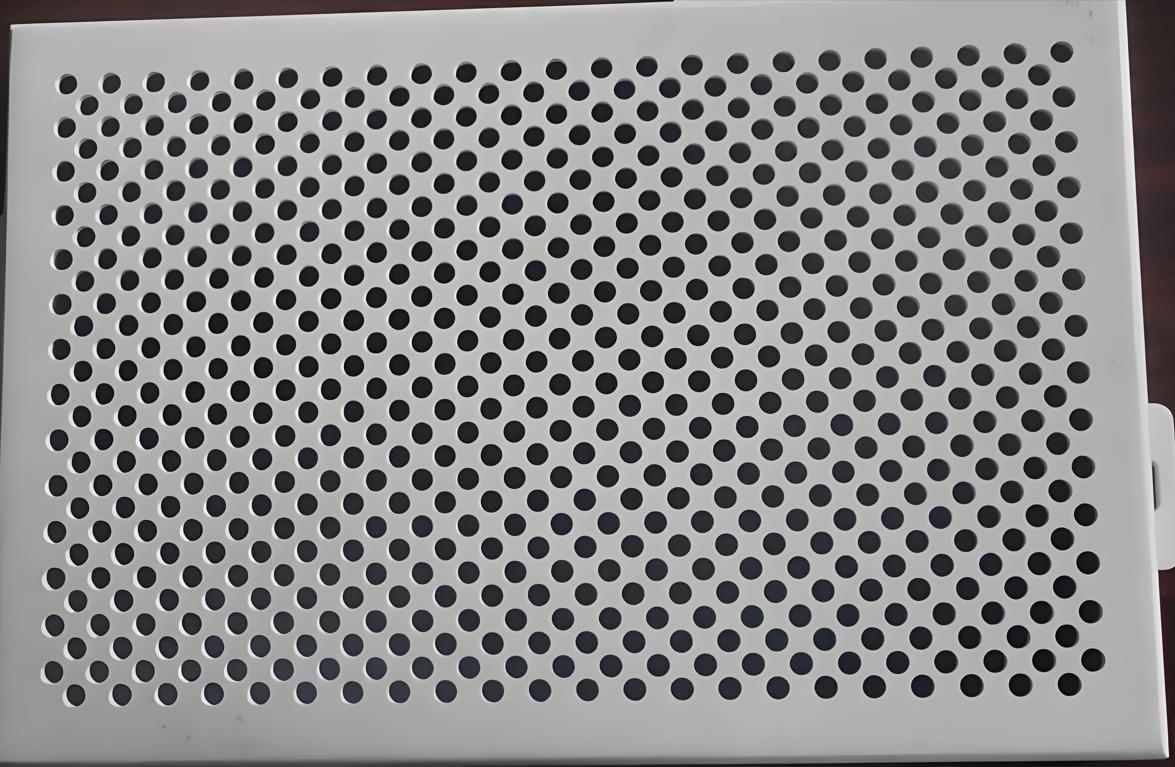

Punching classification

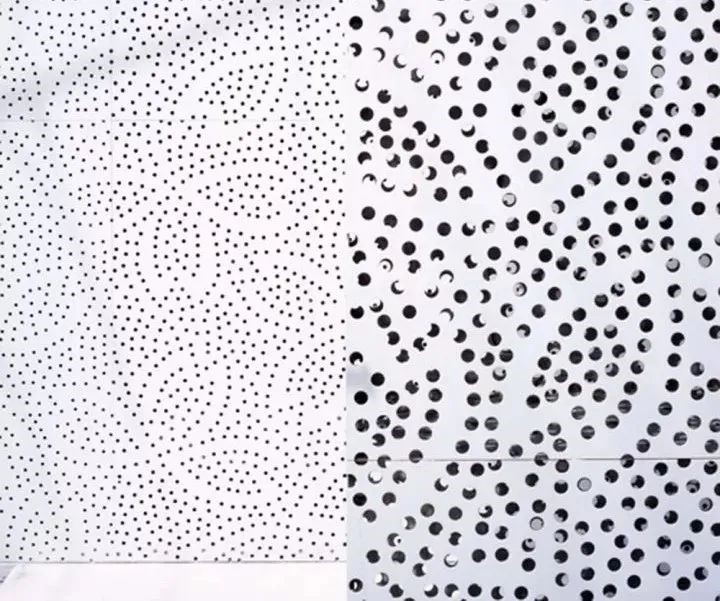

The hole size and pattern of the perforated aluminum plate can be carefully processed and designed according to needs. Holes of different sizes, densities, and shapes form different translucent visual effects.Punching mainly includes rectangular holes, square holes, diamond holes, round holes, oblong holes, hexagonal holes, cross holes, triangular holes, long waist holes, plum blossom holes, fish scale holes, pattern holes, eight-shaped nets, herringbone holes, five-pointed star holes, irregular holes, bulging holes, special-shaped holes, louver holes, etc.

Construction process and installation nodes

Punching method

Commonly used punching methods: CNC punching, stamping process, laser punching.The most common punching method is to use CNC and combination punching machines for large quantities and repeated patterns. Water jet or laser is ideal for creating custom perforations and patterns, with a variety of hole sizes and unique shapes.

Custom perforation patterns and shapes, produced using millimeter precision machines and other new manufacturing technologies, can also achieve an unlimited variety of folding and perforated panel designs.

Perforation rate and aperture

The perforation rate refers to the percentage of the total area of perforated holes within the perforation area.The perforation rate is the core factor affecting the perforated aluminum panel unit of the building surface, and is the key to affecting its visual overall expression and reducing the energy consumption of the building.

According to current mechanical equipment, the maximum perforation rate can reach about 60%, and the perforated aluminum panel size is required to be within the range of 1500*3000. If it exceeds this range, the perforation requires secondary positioning.

The higher the perforation rate of the perforated aluminum panel, the greater the impact on the flatness of the formed aluminum panel, and the inspection standard is lower than the corresponding regulations for normal aluminum panels.

Aperture is one of the factors affecting the perforated aluminum plate unit. Controlling the aperture, hole spacing and arrangement of the punching can affect the visual clarity of the perforated staggered plate surface and create a novel visual effect. Combining factors such as perforation rate and plate thickness can reduce solar radiation heat and energy consumption.

The most common aperture is 6mm and the spacing is 15mm.

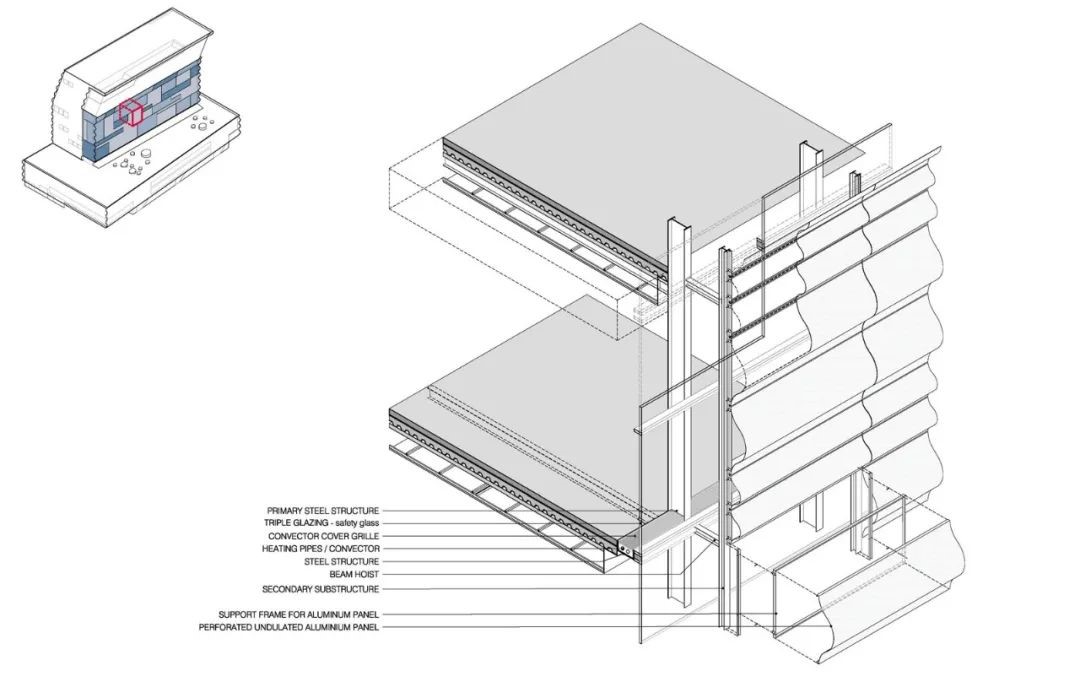

Structural connection of perforated aluminum plate

Connection with the main structure

Because the metal perforated aluminum plate is in the form of a plate and is generally thin, its structural strength is weak. Therefore, when it is used as a building skin, its own strength is not enough to support its direct connection between the main structural connectors of the building. It is usually necessary to set a keel as a supporting member to fix the metal perforated aluminum plate. The keel is connected to the main structure, thus forming the overall construction method of "main structure-keel support system-metal perforated plate".Connection and fixation of perforated aluminum plate

The connection between the perforated aluminum plate and the main structure generally adopts a discontinuous indirect connection method, which mainly includes bolt connection and riveting; the continuous connection methods are mainly welding and bonding.Nowadays, discontinuous connection methods are generally used, because the overall structure of the skin is more resilient, which is convenient for future disassembly, maintenance and renewal. Depending on the metal material, the connection method is also different.

Cost

The price of perforated aluminum plate is mainly determined by its alloy composition, aluminum plate thickness and hole pattern.Generally speaking, the higher the precious metal content in the alloy, the higher the price; the thicker the thickness, the higher the price; the more complex the holes, the higher the price.

The cost of the facade metal perforated aluminum plate process is 800-1000 yuan/square meter (for reference only, whether this cost can be achieved, there is a question mark)

Widely used

Perforated aluminum plate has a variety of hole shapes and different arrangements. It is beautiful in shape and has a very good decorative effect. It is easier to help architects and designers meet their own design ideas and concepts, giving buildings more style and design.Perforated aluminum plates have beautiful shapes, elegant colors, and good decorative effects. They can be used to improve the sound quality of public buildings such as hotels, restaurants, cinemas, and broadcasting studios, as well as medium- and high-end civil buildings. They can also be used in various workshops, factories, and air defense basements as noise reduction measures. They have become the main products that have swept the decoration market in recent years.

Application Cases

External facade curtain wall

The library of Chongqing Real Estate Vocational College combines glass curtain walls and perforated metal plates to form the characteristics of each facade.The interior of the library's large roof adopts the concept of "starry sky". Through the changes in density, four patterns are designed on the perforated aluminum plates. Through careful design and arrangement, a "nebula"-like pattern is formed.

All aluminum plates are spliced with a length and width of 2000mmX1200mm as standard parts, including four patterns of perforated aluminum plates and a solid aluminum plate without holes. A total of five patterns form the pattern on the inner surface of the north roof.

The four perforated aluminum plate patterns are divided into four patterns of ABCD according to the density of the opening rate. On this basis, four patterns of A’B’C’D’ were set up, and the perforated aluminum plates were rotated 180 degrees accordingly, with a total of 9 types of aluminum plates distributed.

The facade of the building wrapped in white perforated aluminum plates in Qingdao Hechang Haiyunxi’an presents a sense of solidity, but does not completely block the light.

The architect designed a unit-type standard gradient perforated aluminum plate module with built-in lighting equipment. Therefore, whether inside or outside the building, whether during the day or at night, the building will present a sense of detail of glittering stars. As the saying goes, "The sun and the moon seem to come out of it, and the stars seem to come out of it."

The color tone and lighting echo the external space, giving people a strong sense of artistic atmosphere in a unified and coordinated manner.

Interior decoration

Perforated aluminum plates can be made into various shapes, which is a good interior decoration.For example, Wutopia Lab created a three-dimensional green landscape with perforated aluminum plates in the old industrial area of Shanghai.

The perforated aluminum plate is used as the brush and ink inside the office building, and the facade, landscape, lobby, office and roof are connected in a freehand landscape style to form a three-dimensional, complete and continuous green landscape scroll.

Wutopia Lab built a bookstore in the metal rainbow in Suzhou - Suzhou Zhongshuge.

The "rainbow" in the room is formed by perforated aluminum plates with petal patterns. When the perforation rate exceeds 50%, the aluminum plate visually loses the texture that the metal should have. The multi-layered aluminum plates are stacked together, like many layers of veils. The metal that has lost its texture eventually creates a hazy and uncertain visual effect, presenting a stunning effect.

Ceiling design

The perforated aluminum plate on the top of the lobby of Chongqing Longhu Chenlinjian and the tree-shaped projection design fully hide the philosophy of life and experience the immeasurable sense of ritual of life.

A certain apartment project in Singapore designed 3 different ceiling designs in the interior, two of which are designed with perforated aluminum plates to filter sunlight into warm light suitable for work and relaxation.

Staircase design

The outdoor staircase built by K+ Space in Thailand is a custom porous aluminum duplex structure that creates a connection between people and space.K+ Space in Thailand ©Spaceshift Studio

The stair railings of Hangzhou Canal Vanke Center Innovation Experience Center are made of orange perforated aluminum panels. This bold and sculptural staircase system visually creates the impression of supporting a floating circular building inside, and becomes the visual focus in the space, guiding people to walk up and down inside the building.

Balcony railing design

The balcony of the apartment below is innovatively designed with perforated aluminum panels. The panel system was fully manufactured when it was delivered to the site, and can be installed very quickly and easily. Not only is the lighting and ventilation good, but privacy and fall protection can also be guaranteed.Tips:

When choosing perforated aluminum panels for a project, you need to pay attention to the following items:

1. Determine the aperture. The aperture is one of the factors affecting the perforated aluminum panel unit. Controlling the aperture, hole spacing and arrangement of the punching can affect the visual clarity of the perforated staggered panel surface and create a novel visual effect. Combining factors such as perforation rate and panel thickness can reduce solar radiation heat and energy consumption.

2. Determine the panel type. The choice of panel type affects the strength of the perforated aluminum panel, which in turn affects the size of the perforated aluminum panel module, the number of keels that serve as a connection, and the overall effect expression.

3. Select the metal alloy and panel thickness. When using perforated aluminum panels, the metal alloy will affect the overall aesthetics of the finished panel. The thickness of the panel will depend on the location of use. Thicker panels are more suitable for environments with greater wind loads.

4. Specify the details of the aluminum panel. For individual projects, it is necessary to decide whether the perforated aluminum panel has a frame and which reinforcement ribs are required.