What is corrugated aluminum sheet?

Corrugated aluminum sheets are made of aluminum coils or sheets pressed by corrugated pressing equipment. They are also called corrugated aluminum sheets metal, pressed aluminum corrugated sheets, etc. Corrugated aluminum sheets are widely used in roofs of factories, warehouses, private houses and other buildings. They are light in weight and easy to install. Anti-corrosion, high strength, and good thermal insulation, heat insulation, and sound insulation effects. It is gradually replacing stainless steel and iron as roofing materials.

Generally, corrugated aluminum sheets can be divided into trapezoidal corrugated sheets and curved corrugated sheet. They are often used as aluminum corrugated panels as the core material, which improves the performance of the product and reduces the amount of material. It is an indispensable material in the construction industry.

Xienuo's hot-selling corrugated aluminum sheets

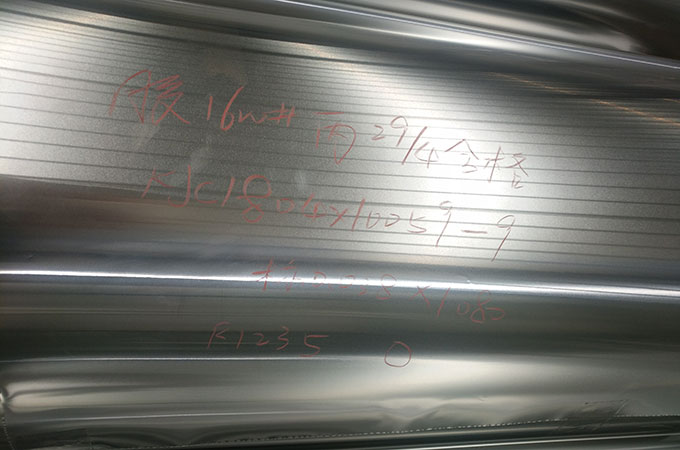

Xienuo is an aluminum corrugated sheet plate manufacturer that can customize production according to customer needs. Xienuo has a complete management system. The corrugated aluminum sheet plate has accurate dimensions and small tolerances, complying with GB/T4438-2006, GB/T 3190, GB/T 3880, GB/ T 228, GB/T 3199 and other standards.

Xienuo can also produce colored corrugated aluminum sheets, with more than 30 colors. The current mainstream coatings are PE and PVDF corrugated aluminum sheets.

Specification

- Alloy: 1050 1060 1100 3003 3004 5005 5052 6061 6063

- Temper: O, H12, H22, H14, H24, H16, H26, H18, H32, H36, H116, H112, H321, T6, T651

- Thickness: 0.2mm-5.0mm,

- Width: 300mm-2900mm

- Length: max 12.5m

- Surface Treatment: mill finished, orange peel, worm pattern, can be covered with plastic film, Or according to your needs

- Wave Type:trapezoidal and curved

- Wave Height:10mm-55 mm

- Coating: Galvanized, PVDF, PE, HDP

- Color: Up to 30 colors for you to choose from

- Standard: GB/T4438-2006、GB/T 3190、GB/T 3880、GB/T 228、GB/T 3199

- Remark: can be customized

Thickness tolerances

| Thickness (mm) | Thickness tolerances on the following widths (mm)(Ordinary) | ||||||

|---|---|---|---|---|---|---|---|

| - | <=1000.0 | >1000.0<=1250.0 | >1250.0<=1600.0 | >1600.0<=2000.0 | >2000.0<=2500.0 | >2500.0<=3000.0 | >3000.0<=3500.0 |

| >0.20-0.40 | ±0.03 | ±0.05 | ±0.06 | - | - | - | - |

| >0.40-0.50 | ±0.05 | ±0.06 | ±0.07 | ±0.08 | ±0.12 | - | - |

| >0.50-0.60 | ±0.05 | ±0.07 | ±0.07 | ±0.08 | ±0.12 | - | - |

| >0.60-0.80 | ±0.05 | ±0.07 | ±0.07 | ±0.09 | ±0.13 | - | - |

| >0.80-1.00 | ±0.07 | ±0.08 | ±0.08 | ±0.10 | ±0.15 | - | - |

| >1.00-1.20 | ±0.07 | ±0.09 | ±0.09 | ±0.11 | ±0.15 | - | - |

| >1.20-1.50 | ±0.09 | ±0.12 | ±0.12 | ±0.13 | ±0.15 | - | - |

| >1.50-1.80 | ±0.09 | ±0.12 | ±0.12 | ±0.14 | ±0.15 | - | - |

| >1.80-2.00 | ±0.09 | ±0.12 | ±0.12 | ±0.14 | ±0.15 | - | - |

| >2.00-2.50 | ±0.12 | ±0.14 | ±0.14 | ±0.15 | ±0.16 | - | - |

| >2.50-3.00 | ±0.13 | ±0.16 | ±0.16 | ±0.17 | ±0.18 | - | - |

| >3.00-3.50 | ±0.14 | ±0.17 | ±0.17 | ±0.22 | ±0.19 | - | - |

| >3.50-4.00 | ±0.15 | ±0.18 | ±0.18 | ±0.23 | ±0.24 | ±0.51 | ±0.57 |

| >4.00-5.00 | ±0.23 | ±0.24 | ±0.24 | ±0.26 | ±0.28 | ±0.54 | ±0.63 |

| >5.00-6.00 | ±0.25 | ±0.26 | ±0.26 | ±0.26 | ±0.28 | ±0.60 | ±0.69 |

| Thickness (mm) | Thickness tolerances on the following widths (mm)(High precision) | ||||||

|---|---|---|---|---|---|---|---|

| - | <=1.000.0 | >1000.0<=1250.0 | >1250.0<=1600.0 | >1600.0<=2000.0 | >2000.0<=2500.0 | >2500.0<=3000.0 | >3000.0<=3500.0 |

| >0.20-0.40 | ±0.02 | ±0.04 | ±0.05 | - | - | - | - |

| >0.40-0.50 | ±0.03 | ±0.04 | ±0.05 | ±0.06 | ±0.10 | - | - |

| >0.50-0.60 | ±0.03 | ±0.05 | ±0.06 | ±0.07 | ±0.11 | - | - |

| >0.60-0.80 | ±0.03 | ±0.06 | ±0.07 | ±0.08 | ±0.12 | - | - |

| >0.80-1.00 | ±0.04 | ±0.06 | ±0.08 | ±0.09 | ±0.13 | - | - |

| >1.00-1.20 | ±0.04 | ±0.07 | ±0.09 | ±0.10 | ±0.14 | - | - |

| >1.20-1.50 | ±0.05 | ±0.09 | ±0.10 | ±0.11 | ±0.16 | - | - |

| >1.50-1.80 | ±0.06 | ±0.10 | ±0.11 | ±0.12 | ±0.17 | - | - |

| >1.80-2.00 | ±0.06 | ±0.11 | ±0.12 | ±0.14 | ±0.19 | - | - |

| >2.00-2.50 | ±0.07 | ±0.12 | ±0.13 | ±0.15 | ±0.20 | - | - |

| >2.50-3.00 | ±0.08 | ±0.13 | ±0.15 | ±0.17 | ±0.23 | - | - |

| >3.00-3.50 | ±0.10 | ±0.15 | ±0.17 | ±0.18 | ±0.24 | - | - |

| >3.50-4.00 | ±0.15 | ±0.18 | ±0.18 | ±0.23 | ±0.24 | ±0.34 | ±0.38 |

| >4.00-5.00 | ±0.18 | ±0.22 | ±0.24 | ±0.25 | ±0.28 | ±0.36 | ±0.42 |

| >5.00-6.00 | ±0.20 | ±0.24 | ±0.25 | ±0.26 | ±0.28 | ±0.40 | ±0.46 |

Aluminum corrugated sheet can be divided into ordinary grade and high precision grade.

When you need a high precision grade, you need to inform in advance and indicate it in the order form (or contract). If not indicated, it will be regarded as ordinary grade.

Length tolerances

Deviation: + 25mm, -10mm.

Width and waveform tolerances

| Wave type code | Width and tolerance | Wave height and allowable tolerance | Wave distance and allowable tolerance | |||

|---|---|---|---|---|---|---|

| - | Width (mm) | Allowable tolerance (mm) | Wave height (mm) | Allowable tolerance (mm) | Wave distance (mm) | Allowable tolerance (mm) |

| Trapezoidal | 1115 |

+25 -10 |

20 | ±2 | 106 | ±2 |

| Curved | 1008 |

+25 -10 |

25 | ±2.5 | 131 | ±3 |

Corrugated aluminum sheets types

Xienuo’s customizable corrugated types include trapezoidal and curved. The following types are commonly produced by Xienuo. If you don’t have what you need, you can contact us and we can produce it according to your needs.

| XN35-125-750(V-125)(trapezoidal) | ||||

|---|---|---|---|---|

|

EFFECT WIDTH(mm) | 750 | ||

| FEEDING WIDTH(mm) | 1000 | |||

| THICKNESS(mm) | 0.5 | 0.6 | 0.8 | |

| SECTION INERTIA(cm4/m) | 11.54 | 13.85 | 18.83 | |

| SECTION RESISTANC(cm4/m) | 6.23 | 7.48 | 10 | |

| XN14-63.5-825(curved) | ||||

|---|---|---|---|---|

|

EFFECT WIDTH(mm) | 825 | ||

| FEEDING WIDTH(mm) | 1000 | |||

| THICKNESS(mm) | 0.5 | 0.6 | 0.8 | |

| SECTION INERTIA(cm4/m) | 1.47 | 1.82 | 2.47 | |

| SECTION RESISTANC(cm4/m) | 2.10 | 2.60 | 3.53 | |

| XN18-76.2-836(curved) | ||||

|---|---|---|---|---|

|

EFFECT WIDTH(mm) | 836 | ||

| FEEDING WIDTH(mm) | 1000 | |||

| THICKNESS(mm) | 0.5 | 0.6 | 0.8 | |

| SECTION INERTIA(cm4/m) | 1.84 | 2.25 | 3.04 | |

| SECTION RESISTANC(cm4/m) | 2.04 | 2.50 | 3.37 | |

| XN18-130-910 | ||||

|---|---|---|---|---|

|

EFFECT WIDTH(mm) | 910 | ||

| FEEDING WIDTH(mm) | 1000 | |||

| THICKNESS(mm) | 0.5 | 0.6 | 0.8 | |

| XN18-127-900 | ||||

|---|---|---|---|---|

|

EFFECT WIDTH(mm) | 900 | ||

| FEEDING WIDTH(mm) | 1000 | |||

| THICKNESS(mm) | 0.5 | 0.6 | 0.8 | |

| XN18-225-900 | ||||

|---|---|---|---|---|

|

EFFECT WIDTH(mm) | 900 | ||

| FEEDING WIDTH(mm) | 1000 | |||

| THICKNESS(mm) | 0.5 | 0.6 | 0.8 | |

| XN18-205-1025 | ||||

|---|---|---|---|---|

|

EFFECT WIDTH(mm) | 1025 | ||

| FEEDING WIDTH(mm) | 1200 | |||

| THICKNESS(mm) | 0.5 | 0.6 | 0.8 | |

| XN18-76.5-1150 | ||||

|---|---|---|---|---|

|

EFFECT WIDTH(mm) | 1150 | ||

| FEEDING WIDTH(mm) | 1200 | |||

| THICKNESS(mm) | 0.5 | 0.6 | 0.8 | |

Advantage

- Light weight, steel is 3 times heavier than aluminum

- Easy to process and shape, convenient and quick to construct

- Beautiful, bright and very effective

- Long service life

- Easy to recycle and have high usability value