What is aluminum jacketing?

Aluminum jacketing is a commonly used product in pipeline protection and insulation. Usually, it is used together with PVC, polyurethane foam, rock wool, glass wool, radial wrap rolled fiberglass, and other insulations. It can protect the insulation and pipes from being damaged by air, water, ultraviolet rays, etc., and it is also called aluminum insulation jacketing, and because it is usually in roll shape, it is also called aluminum roll jacketing.

Aluminum jacketing is commonly used in refrigeration pipes, heat transfer pipes, liquid pipes, and other pipeline systems, such as central air conditioning pipes, power plant and chemical plant pipes, refinery pipes and tanks, etc. It can also be used for the insulation of buildings and equipment.

Early metal jacketing often used white iron, stainless steel, or zinc galvanized steel, compared with iron sheets and steel, aluminum jacketing has the characteristics of light weight, corrosion resistance, anti-static, easy installation, and recyclability. It is gradually replacing other metal jacketing and has become increasingly popular.

Hot-selling aluminum roll jacketing

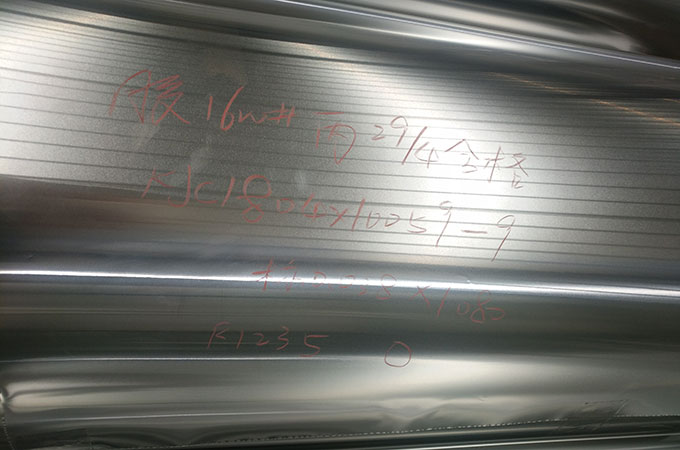

Xienuo is a professional aluminum roll jacketing manufacturer that can be customized according to customer needs. The aluminum jacket alloys we produce for pipe insulation include 1050, 1060, 1100, 3003, 3105, 5005, 5052, which comply with ASTM B209 and ASTM C1729 standards. Xienuo’s Aluminum jacketing is available in smooth, color-coated, orange peel embossed, corrugated, polysurlyn moisture barrier, and kraft paper.

Specifications:

- Alloy: 1050, 1060, 1100, 3003, 3105, 5005, 5052, etc.

- Standard: ASTM B209, ASTM C1729, EN573-1, or according to your needs

- Temper: H14, H16, H24, H26

- Thickness: 0.25mm - 1.5mm

- Width: 914mm, 1000mm, 1200mm, 1219mm and other available widths.

- Lengths: 50' (15 meters), 100' (30 meters), 200' (60 meters), 300' (90 meters), roll (to specified length), flat sheet (cut to length), cut and roll (to specific length)

- Surface: smooth, color-coated, orange peel embossed, corrugated, polysurlyn moisture-proof aluminum sheath, composite kraft paper, etc.

- Shape: Small roll, jumbo roll, sheet

- Inner diameter: 75mm, 150mm, 305mm, 405mm, 505mm (with or without paper core)

- Outer diameter: According to roll weight or customer requirements

- Quantity: Coils of the most regular thicknesses are in stock and can be ordered in small quantities.

According to the specific requirements of customers, Xienuo can also provide additional processing services such as lamination and slitting.

Type

According to aluminum alloy grade

1100 and 1200

1100 and 1200 are both pure aluminum. 1100 aluminum jacketing has the characteristics of low strength, moderate hardness, low price, and good molding performance. It is the most commonly used material for aluminum insulation jacketing and is often used in areas where the surrounding environment is not complex. The anti-corrosion performance of refrigeration pipes, heat transfer pipes, liquid pipes, etc. is not as good as 3000 series aluminum jacketing.

The strength of 1200 aluminum jacketing is higher than 1100, but the molding performance is not as good as 1100 aluminum jacketing

3003 and 3105

3000 series aluminum alloy is an anti-corrosion alloy with high strength, good formability, and corrosion resistance. 3003 aluminum insulation jacketing can be used in pipeline systems with complex environments, such as outdoor pipeline systems, power plant pipelines, and refinery pipeline systems. The price ratio for 1000 series aluminum jacketing is slightly higher.

The strength of 3105 aluminum jacketing is higher than that of 3003, and its molding performance is similar to that of 3003. In most scenarios, 3105 is a good substitute for 3003 aluminum jacketing.

5005 adn 5052

The 5000 series is an aluminum-magnesium alloy with better strength and corrosion resistance than the 3000 series alloy. It has good plasticity, and fatigue resistance and can be welded. Commonly used in chemical plant pipelines, refinery pipelines, etc.

According to surface treatment

Stucco embossed

The pattern has orange peel and modified orange peel. The concave and convex pattern on the surface after embossing can increase the surface area, which is beneficial to heat dissipation and increases strength.

Mill finish

The surface of Mill finish is not conducive to the accumulation of dirt and rainwater, keeps the surface clean for a long time, has high reflectivity, and effectively reduces the internal temperature of the pipe.

Polysurlyn Moisture Barrier

Aluminum roll jacketing with polysurlyn moisture barrier refers to the exposed outer surface of the aluminum roll, which is equipped with a 3 mil thick polysurlyn moisture barrier as standard and is hot laminated to the inner surface to help prevent the corrosion of the sheath and the metal pipes, containers or equipment below.

Kraft paper

The inner layer of Kraft paper aluminum roll jacketing is kraft paper, which is also commonly called kraft paper film. The function of this layer is to provide insulation, while also absorbing and preventing moisture intrusion and protecting the surface of the pipe or equipment.

Corrugated aluminum roll jacketing

It is a material used for pipe and equipment insulation. The corrugated design on the surface of the aluminum jacketing increases the strength and rigidity of the material, making it more resistant to external impacts and extrusion forces.

Application

How thick is aluminum insulation jacket? commonly used thicknesses include 016" (0.4mm), 020" (0.5mm), 024" (0.6mm), 0.7, 032" (0.8mm), etc., Xienuo can also produce aluminum insulation jacketing with other thicknesses according to customer needs: 0.25 mm thickness, 0.3 mm thickness, 0.35 mm thickness, 0.4 mm thickness, 0.45 mm thickness, 0.55 mm thickness, 0.9 mm, 1 mm and other thickness aluminum insulation jacketing. Aluminum jacketing with different thicknesses has different applications.

- 016-inch (0.4 mm): Standard for industrial use, recommended for pipes up to 24" outside diameter, including insulation. It is used to protect pipes less than 8 feet in diameter.

- 020-inch (0.5 mm): Recommended for use on insulation pipelines with an outer diameter of up to 36", including insulation. It is used to protect pipes larger than 8 feet in diameter.

- 024" (0.6mm): increased thickness can more effectively protect insulation and pipes and avoid pipe damage.

- 032" (0.8 mm): suitable for areas where pipes are prone to wear or where extra protection is needed.

Package

Xienuo's packaging method is mainly wooden pallets fixed with steel strips. Each roll can be covered with a blue protective film. Each wooden pallet weighs about 1, 000kg and is wrapped with plastic film to prevent seawater corrosion, and a desiccant is placed inside.

Aluminum jacketing is usually packaged in small rolls, which is convenient for transportation and installation. We can also make it into a jumbo roll and sheet according to needs. The advantage is that it reduces the process, reduces the cost, and shortens the delivery time. The disadvantage is that it is heavy and inconvenient to install.

Why choose aluminum jacketing instead of iron sheet

- Thin thickness, lightweight, easy to transport

- Good mechanical properties, easy to operate and install

- Good corrosion resistance, not easy to be corroded, long service life

- Good aesthetics

- Green materials, are easier to recycle than iron sheets and maintain value

Aluminum jacketing fittings for pipe insulation

In actual duct insulation, we not only need Aluminum insulation jacketing but also many fittings for fixing or connecting. Commonly used fittings are as follows:

- Elbow covers

- Pressed tees

- Pressed endcaps

- Springs

- Strapping and Seals

- Screws and nuts

With these fittings, installation is more convenient. Among them, elbow covers and pressed tees are pressed to form two matching halves. Elbow covers are used at the corners of pipes. Regular ones are 45-degree and 90-degree angles. Two half-piece elbow covers pass through fastened with straps or screws, usually made of 1000 series aluminum. Pressed tees are used at pipe crotches to tightly wrap and protect the insulation and pipe. Aluminum endcaps can be used to seal off the edges between the Tee cover and the OD of the pipe insulation. A third aluminum endcap can be used to close around the valve stem.

Installation guide

Pipe insulation steps

Duct insulation construction technology is a key link in the insulation project. The construction technology includes base treatment, insulation layer construction aluminum jacketing construction (installation), and other steps.

- Base layer treatment: The surface of the base layer (pipeline) is required to be clean, flat, free of oil and loose materials, and necessary waterproofing treatment is required.

- Insulation layer construction: Keep the insulation material flat and firm to ensure the continuity and tightness of the insulation.

- Jacketing installation: Pay attention to the even application of paint and control of drying time to ensure the quality and waterproof performance of the protective layer. Determine insulation and pipe diameters prepare aluminum jacketing and install

Aluminum jacketing installation guide

Preparation before installation: aluminum jacketing, self-tapping nails (length not more than 15mm), rolling machine, rounding machine, electric drill, scissors, steel ruler, tape measure, wallpaper knife, scaffolding and accessories, fittings, such as elbows, tees , endcaps etc.

Installation process:

- Prepare aluminum jacketing of the appropriate size

- Roll into a circle, rolled edge

- Wrap on the pipe that has been covered with insulation

- Fix with self-tapping screws

Key points to note:

- Prepare materials according to the outer circumference of the pipe insulation plus the overlap length of 30mm.

- Shape the prepared aluminum jacketing on the rolling machine.

- Press the prepared aluminum jacketing into circumferential and transverse edge forming on the edge rolling machine.

- Wrap aluminum jacketing tightly on the outer insulation surface of the pipe.

- The metal protective layer (aluminum jacketing) must be fixed circumferentially and transversely using blind rivets.

Why choose us

Xienuo is an aluminum insulation jacketing manufacturer that has been around for 25 years. We have more than 200 skilled aluminum processing engineers and nearly 1, 000 workers.

We have a complete quality management system to ensure that every order meets customer needs. What we are good at is not only aluminum insulation jacketing, but also aluminum sheets, aluminum coils, aluminum foil, roofing materials, downspout materials, aluminum rods, aluminum tubes, etc. The production cycle is fast and the delivery is more timely.

FAQ

What is the jacketing material for insulation?

Metal jacketing often uses white iron, stainless steel or Zinc galvanized steel. The best jacketing material for insulation is aluminum.

What is the difference between a jacket and an insulation?

A jacket is the outermost metal sheath of the pipeline system. Common materials include tinplate, stainless steel, zinc galvanized steel, etc. It is used to protect insulation and pipelines from water, moisture, ultraviolet rays, and chemicals.

Insulation is between jacketing and pipes and is the most important part of pipe insulation. It usually includes PVC, polyurethane foam, rock wool, glass wool, Fiberglass, etc. Their functions and materials are completely different.

What is the difference between thermal insulation and thermal insulation?

Thermal insulation usually specifically refers to the process of preventing heat transfer, while insulation more broadly covers various ways of preventing energy transfer, including not only thermal insulation but also sound insulation, electrical insulation, etc.