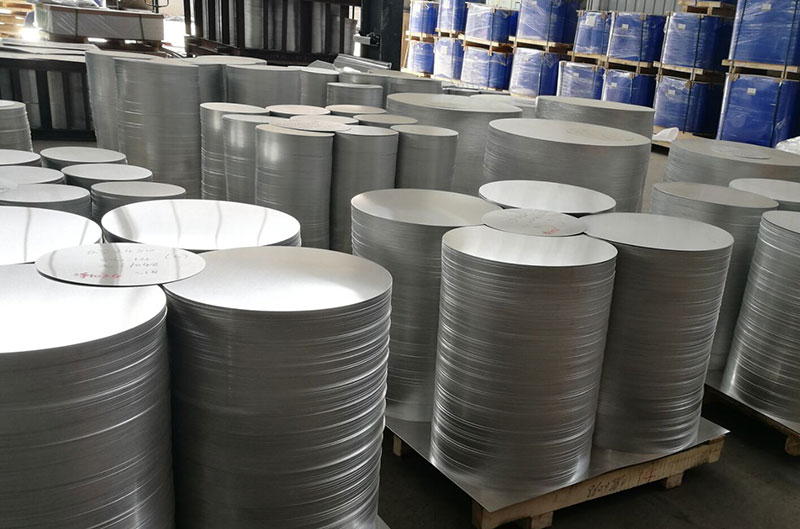

What is a 1060 aluminum circle?

1060 aluminum circle is a round aluminum plate with more than 99.60% aluminum content, and also known as 1060 aluminum disc. It is easy to process and has strong corrosion resistance, good weldability, and electrical conductivity. 1060 aluminum circle is usually made of 1060 sheet, 1060 coil, or 1060 strip after laser cut by cutting, water cutting, or shearing equipment

Many items in the kitchen are produced from 1060 aluminum discs, such as cookware, kitchenware, and fryers. cookware, utensils, Non-stick pan/pot, Bowl or cup. 1060 round aluminum sheets can also be used to make lamps, indicators, Hoses, aerosol cans/boxes, telescopic tubes, aluminum bottles, aluminum caps, etc. Aluminum discs are also used as decorative materials in buildings.

Commonly used alloy tempers are semi-hard (H14, H24) temper

Customizable specifications

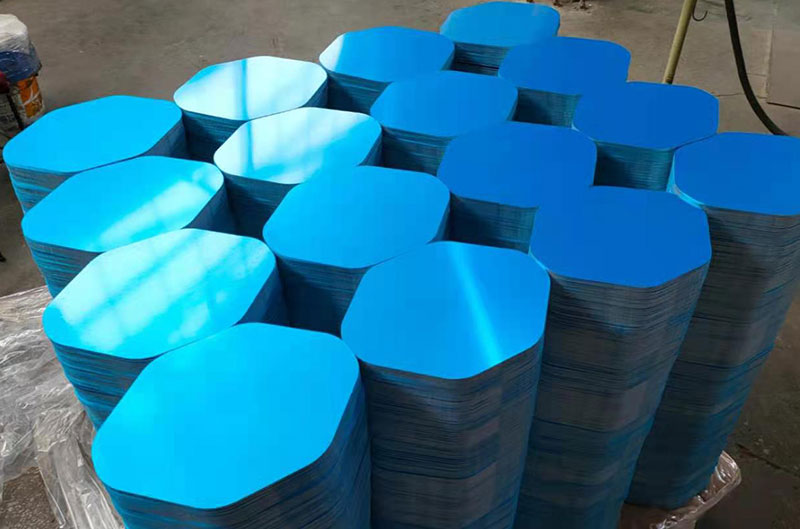

Henan Xienuo can produce 1060 aluminum circles and discs according to ASTM B209, ASME SB209, EN573-1, GB/T3880-2018, and other standards according to your needs. The shapes of the 1060 aluminum circle plates provided by the company are round aluminum circles, square (rounded corners), and oval aluminum discs piece. Comply with RoHS and REACH environmental standards.

The properties of 1060 aluminum circles and discs and 1050 and 1100 aluminum circles and discs are similar. They are both 1000-series pure aluminum discs and can be substituted for each other in some application fields.

Xienuo can also provide additional services: anodizing, lamination (blue film, electrostatic blue film, transparent film, black and white film, laser film), paper clamping, laser engraving, color coating, printing, prepainted, etc.

Please email us for aluminum disc categories or samples, samples for free. Email: sale02@xienuoenterprise.com

Specifications parameters chart

| Item | Content |

|---|---|

| Alloy | 1060 Aluminum circle and disc |

| Temper | O, H12, H14, H16, H18, H111, H22, H24, H26, etc. |

| Process type |

Casting rolling (CC) hot-rolled (DC) Forging CC VS. DC |

| Shape | Circle, square (rounded corners), oval |

| Surface Treatment | Mill finish, coated, anodizing, embossed, stucco, |

| Thickness(mm) | 0.03-10 |

| Thickness tolerance(mm) | Detailed |

| Diameter (mm) | 20-1500, diameter list |

| Quality | Totally free from defects like roll makers, edge damage, oil stain, white rust , dents, scratches, etc. |

| Weight per pallet | Regular 1000kg-3000kg, or according to your needs |

| Standard | AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN, etc. |

| Typical Use | Cookware, lamp cover and road traffic sign, Advertising board, Building decoration, Lamp holder, Fan leafs, Electrical part, Chemical instrument, Machined part, Deep-drawn or spinner part |

| MOQ | Generally, the trial order will be accepted. |

| HS code | 76069100 |

| Lead Time | 7-35 days delivery, global export |

| Price Term | CIF CFR FOB EX-WORK or according to negotiation |

| Payment Term | TT, LC at sight or according to negotiation |

| Packaging and packing | Standard seaworthy export packaging. With protection(covering with brown paper and plastic film). Finally, the aluminum circle is fixed on a wooden pallet/wooden case. 2-3 tonnes in one wooden pallet. 18-22 tonnes in a 1x20' container. |

| Supply Ability | 1, 000 Tons per Month |

| Loading Port | Any port of China, Shanghai Ningbo Qingdao |

Diameter list

| Diameter range | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| >=20 | >=140 | >=170 | >=200 | >=250 | >=300 | >=400 | >=500 | >=600 | >=700 | >=800 |

| 20 | 140 | 170 | 200 | 250 | 300 | 400 | 500 | 600 | 700 | 800 |

| 25 | 141 | 172 | 203 | 252 | 305 | 405 | 505 | 610 | 705 | 810 |

| 93 | 142 | 173 | 205 | 254 | 310 | 410 | 510 | 615 | 710 | 838 |

| 100 | 143 | 175 | 210 | 255 | 312 | 420 | 515 | 619 | 720 | 890 |

| 105 | 144 | 176 | 211 | 258 | 315 | 425 | 520 | 630 | 730 | 902 |

| 109 | 145 | 177 | 212 | 260 | 320 | 430 | 525 | 635 | 740 | 945 |

| 110 | 147 | 178 | 215 | 267 | 325 | 435 | 530 | 645 | 760 | 960 |

| 112 | 149 | 180 | 216 | 268 | 330 | 440 | 540 | 650 | 770 | 1000 |

| 115 | 150 | 181 | 217 | 270 | 335 | 445 | 545 | 655 | 780 | 1150 |

| 118 | 153 | 182 | 218 | 272 | 340 | 450 | 550 | 665 | 1200 | |

| 120 | 154 | 183 | 220 | 274 | 345 | 455 | 560 | 670 | ||

| 121 | 155 | 184 | 221 | 275 | 350 | 460 | 565 | 680 | ||

| 122 | 157 | 185 | 222 | 277 | 355 | 465 | 570 | 690 | ||

| 123 | 158 | 188 | 225 | 278 | 360 | 470 | 575 | |||

| 124 | 160 | 190 | 226 | 280 | 364 | 475 | 580 | |||

| 127 | 161 | 192 | 230 | 282 | 368 | 480 | 585 | |||

| 128 | 162 | 193 | 233 | 285 | 370 | 485 | ||||

| 129 | 163 | 195 | 235 | 290 | 375 | 490 | ||||

| 130 | 164 | 198 | 237 | 292 | 380 | 495 | ||||

| 132 | 165 | 238 | 293 | 385 | ||||||

| 133 | 166 | 240 | 295 | 390 | ||||||

| 134 | 167 | 242 | 395 | |||||||

| 135 | 168 | 245 | ||||||||

| 136 | 169 | 249 | ||||||||

| 137 | ||||||||||

| 138 | ||||||||||

| 139 | ||||||||||

Diameter tolerances

| Blanked and Sheared aluminum Circle Products | |||

|---|---|---|---|

| Thickness(mm) | Diameter Range (D)(mm) | ||

| D <= 455 | 455 < D <=1000 | 1000 < D <=1500 | |

| .4 - 6.0 | +/-.079 | +/-.099 | +/-.018 |

| * The maximum dimension may vary according to individual specifications | |||

1060 Aluminum circles and discs equivalent grades

| STANDARD | UNS |

|---|---|

| Aluminum 1060 | A91060 |

Standard specification for aluminium 1060 circles and disc

- ASTM B209- Standard Specification for Aluminum and Aluminum-Alloy Circles

- ASTM B632 / B632M-Standard Specification for Aluminum-Alloy Rolled Tread Circles

- ASTM B947- Standard Practice for Hot Rolling Mill Solution Heat Treatment for Aluminum Alloy Circles

- ASTM B548- Standard Test Method for Ultrasonic Inspection of Aluminum-Alloy Circles for Pressure Vessels

- AMS 4001- Aluminum Circle, 0.12Cu (1100-0), Annealed

- AMS 4003- Aluminum Alloy, Circle, 0.12cu (1100-H14), Strain Hardened

- AMS QQA250/1- Aluminum 1100 Circle

Properties and Characteristics

Properties

1060 aluminum alloy is formed by adding a small amount of copper to pure aluminium. It is the most common alloy material in the 1000 series.

Component Elements Properties

| Component | Content(%) |

|---|---|

| Iron, Fe | <= 0.35 |

| Silicon, Si | <= 0.25 |

| Copper, Cu | <= 0.05 |

| Manganese, Mn | <= 0.03 |

| Magnesium, Mg | <= 0.03 |

| Zinc, Zn | <= 0.05 |

| Vanadium, V | <= 0.05 |

| Titanium, Ti | <= 0.03 |

| Other, each | <= 0.03 |

| Aluminum, Al | >= 99.60 |

Physical Properties

| Physical Properties | Metric |

|---|---|

| Density | 2.68 g/cm^3 |

| Conductivity | 55% |

| Electrical Resistivity | 0.00000280 ohm-cm - 0.00000283 ohm-cm |

| Annealing Temperature | 343 °C |

Mechenical Property

The mechanical properties (yield strength, elongation, hardness, and tensile strength) of 1060 aluminium circles and discs are also related to the annealing process of the aluminium circle discs. Below, we will introduce the mechanical properties of 1060 aluminum circles based on different annealing temper (for reference only).

| Alloy | Temper | Thickness(mm) | Tensile Strength(Mpa) | The Yield Strength(Mpa) | elongation(%) | hardness(HV) |

|---|---|---|---|---|---|---|

| 1060 | O | 0.2-0.5 | 60-100 | ≥15 | ≥20 | 20-30 |

| 0.5-1.0 | ≥30 | |||||

| 1.0-4.0 | ≥35 | |||||

|

H12 H22 |

0.2-0.5 | 80-120 | ≥60 | ≥12 | 30-40 | |

| 0.5-1.0 | ≥15 | |||||

| 1.0-4.0 | ≥18 | |||||

|

H14 H24 |

0.2-0.5 | 95-135 | ≥70 | ≥6 | 35-45 | |

| 0.5-1.0 | ≥8 | |||||

| 1.0-4.0 | ≥10 | |||||

|

H16 H26 |

0.2-0.5 | 110-155 | ≥75 | ≥2 | 43-55 | |

| 0.5-1.0 | ≥4 | |||||

| 1.0-4.0 | ≥6 | |||||

|

H18 H28 |

0.2-0.5 | ≥125 | ≥85 | ≥2 | 50-65 | |

| 0.5-1.0 | ≥3 | |||||

| 1.0-4.0 | ≥4 | |||||

| H112 | 6 - 12 | as low as 76 | as low as 48 | as low as 10 | ||

| 12 - 25 | as low as 70 | as low as 35 | as low as 20 | |||

| 25 - 80 | as low as 62 | as low as 28 | as low as 25 |

Thermal Properties

| Thermal Properties | Metric | English | Comments |

|---|---|---|---|

| Heat of Fusion | 390 J/g | 168 BTU/lb | |

| CTE, linear |

21.8 µm/m-°C @Temperature -50.0 - 20.0 °C |

12.1 µin/in-°F @Temperature -58.0 - 68.0 °F |

|

|

23.6 µm/m-°C @Temperature 20.0 - 100 °C |

13.1 µin/in-°F @Temperature 68.0 - 212 °F |

||

|

24.5 µm/m-°C @Temperature 20.0 - 200 °C |

13.6 µin/in-°F @Temperature 68.0 - 392 °F |

||

|

25.5 µm/m-°C @Temperature 20.0 - 300 °C |

14.2 µin/in-°F @Temperature 68.0 - 572 °F |

average | |

| Specific Heat Capacity | 0.900 J/g-°C | 0.215 BTU/lb-°F | |

| Thermal Conductivity | 230 W/m-K- 234.2 W/m-K | 1600 BTU-in/hr-ft²-°F - 1625 BTU-in/hr-ft²-°F | |

| Melting Point | 646.1 – 657.2 °C | 1195 - 1215 °F | AA; Typical range based on typical composition for wrought products >= 1/4 in. thickness |

| Solidus | 646.1 °C | 1195°F | AA; Typical |

| Liquidus | 657.2 °C | 1215°F | AA; Typical |

Characteristics

- Excellent elongation and tensile strength

- Good processing performance and high stamping and tensile properties

- Gas welding, hydrogen welding, resistance welding, and brazing

- High plasticity, electrical conductivity, and thermal conductivity

- Easy to withstand different pressure processing, extension, and bending

Production technology

Production process

- Ingot/Master Alloys

- Melting Furnace

- Holding Furnace

- D.C. Caster

- Slab

- Scalper

- Hot Rolling Mill

- Cold Rolling Mill

- Punching

- Annealing Furnace

- Final Inspection

- Packing

- Delivery

Cutting process

1060 aluminum circles and discs are usually cut directly from hot-rolled (DC) or cast-rolled (CC) aluminum coils or aluminum slab. Aluminum circle and discs of different thicknesses are cut in different ways.

| Thickness | Cutting process |

|---|---|

| Less than 3.0 mm | The form of piercing blank feeding directly will be applied. |

| 3.0mm-100mm | The bar cutting, laser cutting, CNC water cutting, and cutting will be used for blank feeding production. |

| higher than 100mm | Aluminum bar sawing and direct production or forging |

Type

- 1060 anodized aluminum circle and disc

- 1060 color coated aluminum circle and disk

- 1060 mirror aluminum circle disc

- 1060 forged aluminum circle disc

- 1060 deep drawing aluminum circle plate

Applications

- Cookware: Stock pots, Fry pans, Tea kettles, Pressure cookers, rice cookers, pizza pans, non-stick pans, electric skillets, restaurant cookware, coffee urns, bakeware, steam irons, woks, stainless cookware bottom plates, bread makers

- Lighting: Recessed Lighting, High Bay Industrial Lighting, Low Bay Industrial Lighting, Street Lighting, Traffic Light Reflectors, Sports Lighting

- Decoration: curtain wall decoration, handicrafts, etc.

- Signage: road signs, signs, billboards

FAQ

Q:what is the difference between DC and CC aluminum circles?

A:Due to different production processes, DC (hot-rolled) and CC (Casting rolling) aluminium circles and discs have different mechanical properties, so the applications will also be different.

DC aluminum circles and discs have perfect deep drawing properties and good surface, they can be used to make cookware, cooking utensils, kitchen metal cans, pans, etc.

Compared with the DC process, the CC aluminum circle plate process is simple, more economical, and lower in price than DC aluminium circles. It is used in scenes that do not require high mechanical performance, such as road signs, crafts, etc.

DC aluminum disk is more suitable for drawing, deep drawing, spinning, and other usage scenarios.

Why choose us?

Xienuo Enterprise is a professional 1060 aluminum circle and disc manufacturer. Our factory is located in Huiguo Town, Gongyi City, Henan Province. The 1060 aluminum circles and discs we can provide comply with RoHS and REACH environmental standards, with a wide range of sizes, many additional processing services, and fast delivery. Fast and can meet your special needs, a true one-stop solution provider.

Xienuo has molds with various specifications, which can produce aluminium circles of different sizes and thicknesses according to your needs, to help you succeed in your careers. Quote please contact us and leave a message.

Our customers are all over the world, and our products are exported to more than 40 countries such as Thailand, Vietnam, South Korea, Malaysia, Singapore, India, Bangladesh, Pakistan, Mexico, etc., Turkey, Saudi Arabia, Qatar, Poland, Sweden, etc. High-quality 1060 aluminum discs and thoughtful after-sales service build our good reputation.

Features:

- Surface- no obvious scratches, oil stains, oxidation, black spots, etc.

- Deep drawing quality- Strictly control the grain size to minimize the "orange peel effect" and avoid undesirable phenomena such as wire drawing, ruffles, and high ear production rate that may occur during post-processing.

- Anodizing quality- supports anodizing treatment, anodizing coloring, sealing or not sealing is optional.

- Heavy gauge circle- Various processing methods, supporting customization of heavy gauge circle

- Edge processing-the edges are burr-free and the rounded edges are customizable

- Advanced production and testing equipment and technology- improve the production efficiency of circles and material utilization, shorten the cycle, and ensure the accuracy of the circles provided