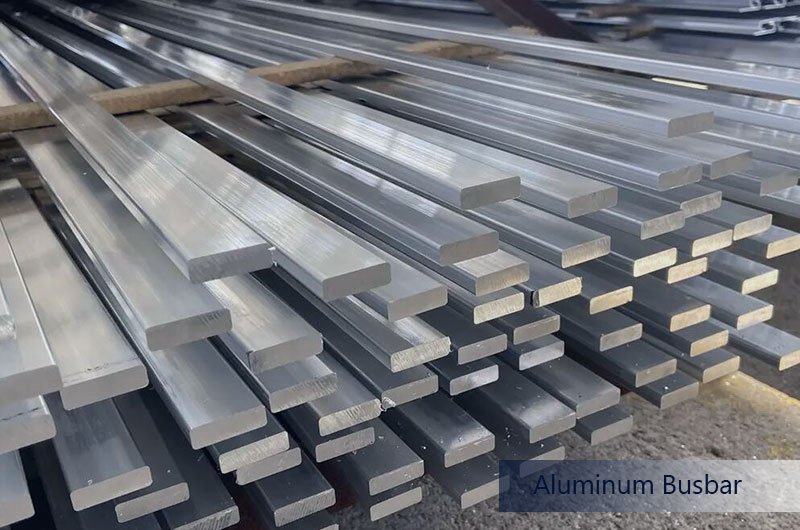

What is aluminum bus bar?

Electrical grade aluminum busbar, also known as EC-grade aluminum busbar, is mainly used in high and low-voltage electrical appliances, switch cabinets, power cabinets, control cabinets, and other electrical equipment to play the role of circuit connection and current transmission.

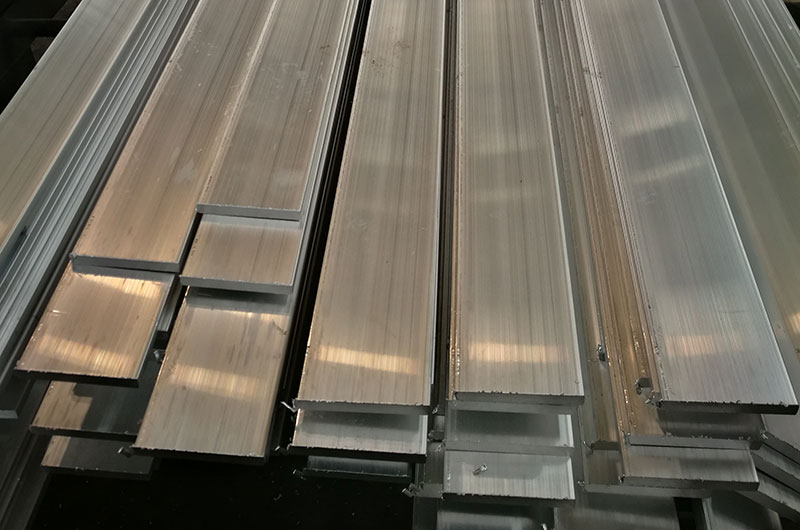

The surface of the Aluminum busbar usually needs to be insulated, and together with the bus duct and bus connector, it forms an aluminum busway. Aluminum busbar is usually made of 1000 series aluminum and 6000 series aluminum.

Hot selling aluminum busbar

Xienuo's EC-grade aluminum busbars can be produced according to ASTM B317, ASTM B236, IEC 60105, ISO 209-1, 2, DIN EN 755-2, EN 573-3, and other standards.

We support conductivity testing, temperature rise testing, bending testing, etc. It supports Insulation coating and Insulating sleeves and supports customized rolled and Special-shaped aluminum busbars. Products similar to aluminum busbars include Aluminum bus ducts and aluminum tubular busbars, which are also widely used in power systems.

Basic information

- Alloy: 1050, 1060, 1070, 3A21, 1100, 1350, 6061, 6063, 6082, 6101

- Temper: T3, T4, T5, T6, T8, H14, H16, H19, T4, T5, T52, T6, T61, T63, T64, T65, T66

- Thickness: 0.15mm-50mm

- Width: 5mm-300mm

- Length: usually up to 6000mm

- Regular Edge: Sharp Edge, Half Round, Full Round

- Standard: ASTM B317, ASTM B236, ISO 209-1, 2, DIN EN 755-2, DIN EN 755-5:2008-06, IEC 60105

- Insulation coating: powder coating, epoxy resin coating or insulation paint coating, etc.

- Insulating sleeve: polyvinyl chloride (PVC), heat shrink tubing, or silicone rubber, etc.

- Surface treatment: Anodizing, electroplating, spraying, etc.

- Special-shaped aluminum busbar: customizable

- Electroplating: Nickel, silver, tin, etc. can be plated according to the installation environment. Among them, if it is tin plating, the conventional electroplating layer is 3-5μm, and the electroplating layer can be customized.

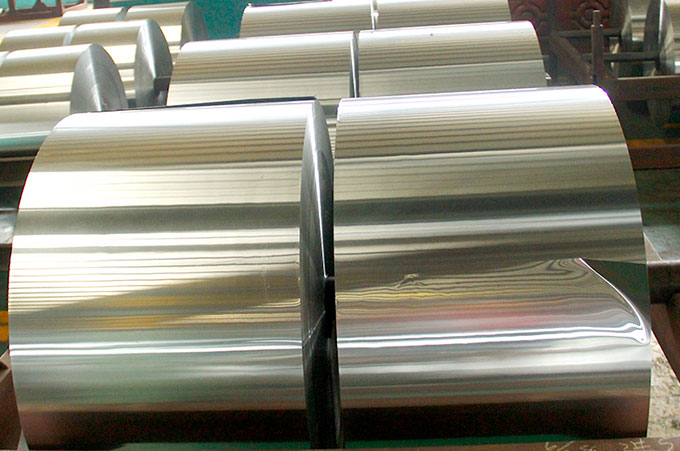

- Production process: extrusion and rolling

- Minimum Bend Radius: 1x thickness (up to 12mm) 2x thickness (>12mm)

- Test: Conductivity test, temperature rise test, bending test, etc.

According to the specific requirements of customers, Xienuo can also provide cutting, stamping, bending, drilling and other processing services.

Tolerance

Width tolerance

| Width range(mm) | Width tolerance(mm) |

|---|---|

| Width range(mm) | Width tolerance(mm) |

| <=35.50 | ±0.40 |

| 35.50 - 100.00 | ±0.80 |

| >100 | ±1.20 |

Thickness tolerance

| Thickness range(mm) | Thickness tolerance(mm) |

|---|---|

| <=6.30 | ±0.15 |

| 6.30 - 12.50 | ±0.20 |

| >12.50 | ±0.30 |

Conductivity and resistivity

| Alloy | Conductivity (% IACS)(20°C) | Resistivity (Ω·m)(20°C)(dc) | Volume conductivity(MS/m)(20°C) | CTE, linear (µm/m-°C)(20-200°C) |

|---|---|---|---|---|

| 1060 | 61-63 | 0.0280 - 0.0285 | 52-60 | 23.6-24.5 |

| 1350 | 61-63 | 0.0276 - 0.0285 | 56-59 | 23.8-24.5 |

| 6060 | 30-35 | 0.028 - 0.033 | 30-35 | 23.4-24.5 |

| 6061 | 40-43 | 0.025 - 0.028 | 40-43 | 23.4-24.5 |

| 6063 | 28-34 | 0.033 - 0.040 | 27-34 | 23.4-24.5 |

| 6082 | 30-34 | 0.033 - 0.037 | 30-34 | 23.4-24.5 |

| 6101 | 54-58 | 0.017 - 0.019 | 54-58 | 23.4-24.5 |

Chemical composition

What is the composition of the aluminum busbar? The composition of aluminum busbars of different alloys is different. Please list the elemental compositions of various aluminum busbars below:

| Component | Content(max%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Elements | 1050 | 1060 | 1070 | 1350 | 6060 | 6061 | 6063 | 6082 | 6101 |

| Silicon, Si | 0.25 | 0.25 | 0.2 | 0.1 | 0.30-0.6 | 0.20-0.6 | 0.7 – 1.3 | 0.3-0.7 | |

| Iron, Fe | 0.40 | 0.35 | 0.25 | 0.4 | 0.10-0.30 | 0.7 | 0.35 | 0.50 | 0.5 |

| Magnesium, Mg | 0.05 | 0.03 | 0.03 | 0.35-0.6 | 0.8-1.2 | 0.45-0.9 | 0.06-1.20 | 0.35-0.8 | |

| Zinc, Zn | 0.05 | 0.05 | 0.04 | 0.05 | 0.15 | 0.25 | 0.10 | 0.20 | 0.1 |

| Manganese, Mn | 0.05 | 0.03 | 0.03 | 0.01 | 0.10 | 0.15 | 0.40-1.00 | 0.03 | |

| Titanium, Ti | 0.03 | 0.03 | 0.03 | 0.01 | 0.10 | 0.15 | 0.10 | 0.10 | |

| Copper, Cu | 0.05% | 0.05 | 0.04 | 0.05 | 0.10 | 0.15-0.4 | 0.1 | 0.1 | |

| Vanadium, V | 0.05 | 0.05 | 0.01 | ||||||

| Cr | 0.01 | 0.05 | 0.04-0.35 | 0.10 | 0.25 | 0.03 | |||

| B | 0.05 | 0.06 | |||||||

| Aluminum, Al | >=99.5 | >=99.6 | >=99.7 | >=99.5 | Remainder | Reminder | Remainder | Remainder | Remainder |

Mechanical properties

| Alloy-temper | Yield Strength Rp0.2(Mpa) | Ultimate tensile strength Rm(Mpa) | Elongation | Conductivity %IACS | Thermal conductivity (W/(m·K))(20°C) |

|---|---|---|---|---|---|

| 6101-T6 | >=172 | >=200 | 15 | - | 200-220 |

| 6101-T61 | >=55 | >=103 | - | >=59 | |

| 6101-T63 | >=150 | >=185 | - | >=56 | |

| 6101-T64 | >=55 | >=105 | - | >=59.5 | |

| 6101-T65 | - | - | - | >=58 | |

| 6063-T4 | 65 | 130 | 14 | 28-34 | 201-218 |

| 6063-T5 | 110-130 | 160-175 | 7-8 | ||

| 6063-T6 | 160-170 | 195-215 | 8 | ||

| 6063-T66 | 10-25 | 225-245 | 8 | ||

| 6082 | 240 | 295 | 8 | 30-34 | 200-215 |

| 6060-T4 | 60 | 120 | 16 | 30-35 | 160-205 |

| 6060-T5 | 120 | 160 | 8 | ||

| 6060-T6 | 150 | 190 | 8 | ||

| 6060-T66 | 160 | 215 | 8 | ||

| 1060 | 85 | 155 | 35 | 61-63 | 210-230 |

| 1350 | 80 | 150 | 35 | 61-63 | 235-240 |

Package

The packaging of Xienuo's aluminum busbars is mainly wooden pallets and wooden boxes. The aluminum busbars are wrapped in plastic film, and a desiccant is placed inside to ensure that the aluminum busbars will not be oxidized due to high moisture. It should be packaged in bundles, according to customer needs.

Busbar design principles

The design principles of the busbar should comprehensively consider factors such as power load, maintenance, reliability, and cost.

Cross-sectional area

The optimal cross-sectional area of the busbar is determined based on the load. The cross-sectional area of the aluminum busbar is usually larger than the copper busbar's to reduce the temperature rise.

Conductivity and electrical insulation

The material of the busbar should have good electrical conductivity and electrical insulation properties to reduce the occurrence of resistance and arc phenomenon.

Linear expansion and its physical properties

Combined with the environment in which the aluminum busbar is used, select a busbar with suitable linear expansion and other physical properties.

Ease of maintenance

The laying of busbars should be convenient for access, inspection, insulation protection, and maintenance.

Common aluminum busbar alloys

1060 aluminum bus bar

1060 aluminum bus bar has the characteristics of good corrosion resistance, high electrical conductivity, and good mechanical properties. It is usually formed by extrusion or rolling. But the disadvantage is low strength.

1350 aluminum bus bar

1350 aluminum bus bar is one of the commonly used electrical grade aluminum bus bars and is often used as battery bus bar material. It has very good electrical conductivity, thermal conductivity, and excellent corrosion resistance. However, like other 1000 series aluminum busbars, 1350 has low mechanical strength and cannot be strengthened by heat treatment.

6063 aluminum bus bar

6063 aluminum bus bar is made of magnesium and silicon as alloy elements. It has good mechanical properties, welding properties, and machining properties. It can be strengthened by heat treatment, so it has high strength, but its electrical conductivity is not as good as 1060, 1350, and other aluminum alloy bus bars.

6101 aluminum bus bar

6101 aluminum alloy busbar contains magnesium and silicon, which has high mechanical strength without significantly reducing electrical conductivity. Yield strength higher than 1350, better creep resistance than 1350. It is also one of the most commonly used busbar alloys.

Connection of aluminum busbars in bus duct

In aluminum busway systems, there is usually no need to weld the aluminum busbars. Instead, connections are usually made through specially designed connectors (connection terminals), which are usually of the bolt or nut type.

Benefits of using connectors include:

- Easy maintenance

- Flexibility

- Avoid thermal effects

The design of connectors usually takes into account factors such as corrosion protection, electrical conduction, and structural strength to ensure system reliability and safety.

Type of Busbar

Which metal is used for busbar? According to the busbar material, common busbars can be divided into:

- Aluminum busbar

- Copper busbar

- Steel busbar

According to the processing technology, common busbars are divided into:

- Tinned aluminum busbar: It solves the problem that aluminum is easily oxidized in the air. However, the resistivity of tin is much higher than that of aluminum. Due to the skin effect of current, the current carrying capacity of the tinned aluminum busbar is relatively reduced

- Copper clad aluminum busbar: It is a good solution to problems such as the skin effect of current, but the process is difficult

- Double coated aluminum busbar: The surface of the aluminum busbar is first plated with copper and then tin. The process requirements are high and the cost is high. There is no problem of linear thermal expansion coefficient. Secondly, the lower resistance copper plating improves the conductivity of the aluminum busbar. The tin plating It prevents direct contact between aluminum and copper dielectrics and air, and improves the anti-corrosion ability of conductors

Aluminum vs copper bus bar

Which is better aluminum or copper bus bar?

Compared with copper busbars, aluminum busbars have significant advantages, such as lighter weight and better economy, but they also have many disadvantages. For example, aluminum's electrical conductivity is lower than copper busbars, and its heat dissipation performance is not as good as copper busbars.

In order to solve the problem of temperature rise, engineers have a good solution. We can increase the surface area of the aluminum busbar to achieve better heat exchange and increase the cross-sectional area of the aluminum busbar to obtain greater carrying capacity.

Although the weight of aluminum busbars has been reduced, the volume has increased a lot. This brings trouble to installation in the limited available space. However, usually, compared with the advantages of aluminum busbars, usually, this is acceptable.

Performance comparison

The electrical conductivity of copper busbar is second only to that of silver, and it is reliable in use, but it is heavy and high in price. The aluminum busbar is light in weight, low in price, and second only to copper in electrical conductivity. However, if it is overlapped, it has the following fatal weaknesses:

The surface of aluminum is easily oxidized, and the contact resistance at the overlapping surface will increase, causing heat and even burning.

The material is soft and has a fast creep rate. It will easily loosen after a long time after tightening, and may heat up or even burn due to poor contact.

| parameter | T2 copper busbar | Aluminum bus bar | Copper clad aluminum busbar |

|---|---|---|---|

| DC resistivity | 0.017777 | 0.029 | 0.025 |

| Conductivity IACS% | 97 | 59.5 | 69 |

| Ampacity (assuming T2 Copper bus bar is 100) | 100 | 78 | 86 |

| Density | 8.89g/cm³ | 2.7g/cm³ | 3.94g/cm³ |

| surface contact resistance | Small | big | Same as copper busbar |

| Antioxidant properties | Good, the oxide layer does not affect conductivity | Poor, the oxide layer resistance is large | Same as copper busbar |

| Creep | Small | big | Small |

| Electrical life | long | short | long |

| Cost-effectiveness | High price, good performance | Low price, poor performance | Best value for money |

Bus bar ampacity comparison

| Copper and aluminum bus bar ampacity comparison chart | |||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Width/Thickness(mm) Emission structure | 15×3 | 20×3 | 25×3 | 30×4 | 40×4 | 40×5 | 50×5 | 50×6 | 60×6 | 60×8 | 60×10 | 80×6 | 80×8 | 80×10 | 100×6 | 100×8 | 100×10 | 120×8 | 120×10 | 2 pcs | 2 pcs | ||

| 60×6 | 80×8 | ||||||||||||||||||||||

| Copper BusBar TMY | turn on | lay flat | 162 | 212 | 264 | 368 | 485 | 540 | 660 | 740 | 873 | 1018 | 1140 | 1115 | 1270 | 1430 | 1356 | 1565 | 1785 | 1860 | 1980 | 1340 | 1950 |

| Put vertically | 171 | 275 | 285 | 335 | 510 | 580 | 705 | 775 | 920 | 1070 | 1195 | 1205 | 1370 | 1540 | 1475 | 1685 | 1870 | 1955 | 2170 | 1410 | 2120 | ||

| seal | 130 | 175 | 215 | 315 | 400 | 440 | 540 | 605 | 718 | 837 | 935 | 915 | 1040 | 1170 | 1120 | 1280 | 1420 | 1485 | 1626 | 1017 | 1530 | ||

| Weight per meter (kg) | 0.40 | 0.53 | 0.66 | 1.04 | 1.40 | 1.74 | 2.18 | 2.61 | 3.13 | 4.18 | 5.22 | 4.18 | 5.57 | 6.96 | 5.22 | 6.96 | 8.70 | 8.35 | 10.50 | 6.26 | 11.14 | ||

|

Aluminum busbar LMY |

turn on | lay flat | 127 | 166 | 205 | 283 | 372 | 417 | 515 | 573 | 680 | 788 | 895 | 864 | 995 | 1115 | 1070 | 1220 | 1370 | 1420 | 1550 | 1035 | 1510 |

| Put vertically | 134 | 175 | 215 | 300 | 395 | 440 | 546 | 600 | 715 | 830 | 935 | 935 | 1070 | 1200 | 1160 | 1315 | 1475 | 1550 | 1760 | 1090 | 1650 | ||

| seal | 104 | 136 | 168 | 235 | 305 | 342 | 422 | 470 | 560 | 648 | 730 | 708 | 815 | 915 | 885 | 1000 | 1120 | 1177 | 1270 | 786 | 1191 | ||

| Weight per meter (kg) | 0.12 | 0.16 | 0.20 | 0.32 | 0.43 | 0.54 | 0.68 | 0.81 | 0.97 | 1.30 | 1.62 | 1.30 | 1.73 | 2.16 | 1.62 | 2.16 | 2.70 | 2.60 | 3.24 | 1.94 | 6.46 | ||

Bus bar ampacity calculation formula

Copper bus bar: Copper busbar current carrying capacity = 1.2 * Busbar width in mm * Thickness in mm Amps

Aluminium bus bar: Aluminium busbar current carrying capacity = 0.8 * Busbar width in mm * Thickness in mm Amps

Example:

Calculate the 120 x 25 mm aluminium and copper busbar current carrying capacity

Copper bus bar carries 3600 Amps (1.2 x 120 x 25) current

Aluminium bus bar carries 2400 Amps (0.8 x 120 x 25) crrent

Installation and maintenance

The reasonable design and implementation of aluminum busbar installation solutions are crucial to the normal operation of electrical equipment and the safety of the power supply.

By comprehensively considering factors such as design principles, material selection, and construction points, the reliability and efficiency of the busbar installation plan can be ensured, and a stable power supply guarantee can be provided for the operation of electrical equipment.

Installation points

Laying planning: Make sure the busbar laying is simple, orderly, and beautiful, and try to avoid cross-laying with other equipment and lines to reduce the possibility of interference and failure.

Trough laying: Put the busbar into a metal trough and fix it with a covering or supporting device. It is suitable for smaller loads or parallel laying.

Pipe laying: Put the busbar into the pipe, suitable for large current loads or complex laying situations.

Insulation protection: To ensure the safe operation of the electrical system, measures such as insulating sheets and insulating sleeves should be taken to effectively protect the busbar from mechanical damage and insulation damage.

Overload protection: Overload protection devices such as fuses, circuit breakers or current protection devices can be selected as needed to prevent electrical equipment from failing to operate normally due to bus overload.

Maintenance

In long-term use, aluminum bus bars suffer from corrosion, linear expansion and contraction, and loose connectors or fasteners between aluminum bus bars, which further increases the risk. To avoid trouble, we need to perform regular maintenance and upkeep on our bus way system.

Aluminum busbar size for your reference

Sharp edge bus bar size list

| Aluminum flat bar with sharp edge size chart | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 2mm | 2*30 | 2*40 | 2*67 | 2*70 | 2.5* 25 | |||||

| 3mm | 3*10 | 3*15 | 3*20 | 3*25 | 3*30 | 3*40 | 3*50 | 3*60 | 3*67 | 3*75 |

| 3*110 | ||||||||||

| 4mm | 4*10 | 4*15 | 4*20 | 4*25 | 4*30 | 4*40 | 4*45 | 4*50 | 4*60 | 4.6*60 |

| 4.8*9.8 | ||||||||||

| 5mm | 5*15 | 5*20 | 5*25 | 5*30 | 5*35 | 5*40 | 5*50 | 5*60 | 5*80 | 5*100 |

| 6mm | 6*20 | 6*25 | 6*30 | 6*40 | 6*50 | 6*54 | 6*55 | 6*60 | 6*65 | 6*70 |

| 6*75 | 6*80 | 6*100 | 6*120 | 6*150 | 6*160 | |||||

| 6.3mm | 6.3*50 | 6.3*63 | 6.3*63.5 | 6.3*80 | 6.35*50.8 | 6.35*76.2 | ||||

| 7mm | 7.6*80 | 7*150 | 7*4*20*4 | |||||||

| 8mm | 8*11 | 8*30 | 8*40 | 8*50 | 8*51 | 8*60 | 8*63 | 8*63.5 | 8*65 | 8*70 |

| 8*80 | 8*90 | 8*100 | 8*120 | 8*125 | 8.8*28.6 | |||||

| 9mm | 9*170 | 9*125 | 9. 2*64 | |||||||

| 10mm | 10*20 | 10*25 | 10*30 | 10*40 | 10*45 | 10*50 | 10*60 | 10*63 | 10*65 | 10*70 |

| 10*80 | 10*90 | 10*100 | 10*110 | 10*114 | 10*120 | 10*125 | 10*140 | 10*150 | 10*160 | |

| 12mm | 12*30 | 12*40 | 12*45 | 12*50 | 12*60 | 12*70 | 12*76 | 12*80 | 12*100 | 12*120 |

| 12*125 | 12*130 | 12*140 | 12*150 | 12*160 | ||||||

| 12.5mm | 12.5*90 | 12.5*100 | 12.5*125 | 12.5*127 | 12.7*101.6 | 12.7*160 | ||||

| 13mm | 13*125 | 13*130 | 13*160 | |||||||

| 14mm | 14*100 | 14*120 | 14.5*80 | |||||||

| 15mm | 15*30 | 15*35 | 15*50 | 15*60 | 15*80 | 15*100 | 15*120 | 15*125 | 15*150 | |

| 16mm | 16*30 | 16*90 | 16*100 | 16*110 | 16*125 | 16*130 | 16*140 | 16*150 | 16*160 | |

| 20mm | 20*76 | 20*100 | 20*120 | 20*130 | ||||||

| Regular square busbar with sharp edge size chart | |||

|---|---|---|---|

| Square bar | 19*19 | 30*45 | 15*15 |

| Round busbar with sharp edge size chart | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Round bar | Φ6 | Φ8 | Φ10 | Φ11 | Φ12 | Φ14 | Φ15 | Φ15.6 | Φ16 | Φ18 |

| Φ20 | Φ21 | Φ22 | Φ23 | Φ25 | Φ27 | Φ28 | Φ30 | Φ32 | Φ35 | |

| Φ38 | Φ40 | Φ45 | Φ50 | Φ55 | Φ60 | |||||

Round edge busbar

| busbar with round edge size chart | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 2mm | R2*20 | R2.5* 50 | |||||||

| 3mm | R3*30 | R3*40 | R3*50 | R3*60 | R3*80 | R3*100 | R3*120 | R3*160 | |

| 4mm | R4*25 | R4*30 | R4*35 | R4*40 | R4*50 | R4*60 | R4.1*44.1 | R4.7*151 | |

| 5mm | R5*30 | R5*35 | R5*40 | R5*45 | R5*50 | R5*60 | R5*70 | R5*75 | R5*80 |

| R5*90 | R5*100 | R5*120 | |||||||

| 6mm | R6*40 | R6*50 | R6*60 | R6*70 | R6*80 | R6*100 | R6*120 | R6*140 | R6*160 |

| R6.3*63 | R6.35*76.5 | ||||||||

| 7mm | R7*70 | ||||||||

| 8mm | R8*40 | R8*50 | R8*60 | R8*80 | R8*100 | RS*120 | |||

| 10mm | R10*20 | R10*40 | R10*50 | R10*60 | R10*75 | R10*80 | R10*100 | R10*120 | R10*125 |

| R10*150 | R10*160 | R10*170 | R10.4*25 | ||||||

| 12mm | R12*80 | R12*100 | R12*110 | R12*120 | R12*125 | R12*150 | R12*160 | ||

| 12.5mm | R12.5*80 | R12.5*125 | R12.7*90 | R12.7*127 | |||||

| 13mm | R13*120 | R13*125 | |||||||

| 14mm | R14*100 | R14*120 | R14*150 | ||||||

| 15mm | R15*100 | R15*120 | R15*130 | R15*150 | |||||

| 16mm | R16*150 | R16*160 | |||||||

| 19mm | R19.05*101.6 | R19.05*127 | |||||||

| 20mm | R20*80 | R20*120 | R20*130 | ||||||

Special-shaped hypotenuse

| Special-shaped hypotenuse size chart | ||||||||

|---|---|---|---|---|---|---|---|---|

| *4*50 | *5*50 | *5*60 | *6*40 | *6*50 | *6*60 | *6*80 | *8*60 | *8*80 |

| *8*100 | *8*120 | *10*40 | *10*80 | *10*100 | *10*120 | *12*80 | *12*100 | *12*120 |

| *15*120 | *20*130 | *28*60 | ||||||

Why choose us

Xienuo Enterprise is a professional aluminum busbar manufacturer in China. The factory is located in Gongyi City, Henan Province, providing a complete set of aluminum solutions for power applications. Our customers include Siemens, Midea, ABB, HITSCHI, etc. Some alloys are in stock and shipped quickly.

Quality assurance

- The surface is smooth, clean, free of oil stains, spots and other defects

- Deep processing of aluminum busbar

- No burrs on the edges

- The oxide layer is uniform and dense, with good corrosion resistance

FAQ

Q:Are you a factory?

A: Yes, we are 100% aluminum busbar factory, welcome to visit.

Q: What is the minimum order quantity for aluminum busbars?

A: Normally, we accept a small trial order

Q:What are your payment methods?

A:T/T, L/C

Q:What is temperature rise?

A: Temperature rise is the difference between the bus surface temperature and the ambient temperature. Therefore, the unit of temperature rise can be either Kelvin temperature scale or degrees Celsius (℃), and the two values are the same. Aluminum busbars generally require a larger surface area than copper busbars, which is more conducive to heat dissipation.

Q:Is aluminum OK for bus bar?

A: Of course, yes, in some specific usage environments, aluminum busbars have more advantages than copper busbars, such as being lighter in weight and more economical.

Q:What grade aluminum is bus bar?

A: Aluminum bus bars usually use 1060, 1350, 6063, 6101 grade aluminum, which has high conductivity and stable performance. It is increasingly replacing copper bus bars.